Achieving an 85% Aluminium Drinks Can Recycling Rate by 2020

The publication of the National Audit Office's review of the packaging recycling obligation system, followed by the Local Government Association press release regarding the alleged high rate of plastic packaging that is unrecyclable, make for depressing reading, and feeds the widespread public concern as to what is really happening to the packaging they recycle.

I am frustrated by such headlines. The focus on plastic packaging is eclipsing all forms of packaging, which means people are unaware of the progress being made in other material sectors.

Aluminium is energy-intensive to produce, yet once in circulation it can be recycled again and again, without any loss of quality. Every tonne of aluminium packaging recycled saves up to 95% of the energy needed to make the metal from raw materials – it is a fantastic example of closed loop recycling and makes aluminium an essential component of the circular economy. That is why the aluminium packaging industry has been acting and investing to increase recycling rates for many years – it makes good environmental sense and it makes good commercial sense too.

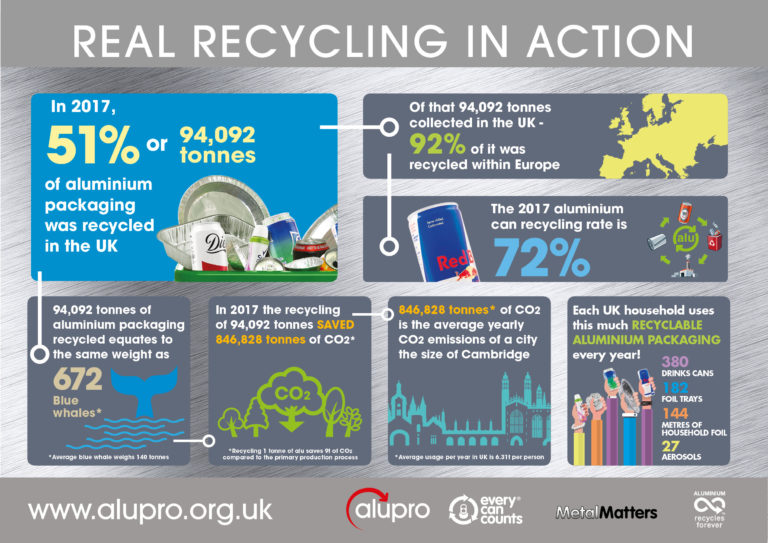

The facts are overwhelming. 75% of the aluminium ever produced worldwide is still in circulation today. The UK has the capacity to recycle all the aluminium cans sold in the UK. In 2017, 72% of aluminium cans were recycled in the UK. 92% of the aluminium packaging collected for recycling in the UK is recycled within Europe. This is what can be achieved with the right investment and infrastructure.

We want to achieve and surpass the highest aluminium packaging recycling rates in Europe, and we have confidence that this is possible, within the existing system. A recent reportcommissioned by Alupro demonstrates how an 85% recycling rate for aluminium cans will be achieved by 2020.

The report, ‘Achieving an 85% Recycling Rate by 2020’, analyses scenarios based on anticipated recycling rates with a future scenario in which a deposit return scheme (DRS) is implemented. This modelling predicts a modest 4% increase in the number of aluminium cans recycled with a DRS; it could be argued that a DRS may not be the most cost-effective solution, and that it makes more sense to improve the existing infrastructure. Of course, any increase in recycling rates is welcomed, but at what cost?

The implications if aluminium cans are included in a DRS are substantial.

Aluminium packaging has a high value and makes a significant contribution to local authority finances, when captured through kerbside collections. Approximately 94,000 tonnes of aluminium packaging was recycled last year, generating an estimated £75m income for councils and waste re-processors.

Our priority is to ensure that aluminium packaging is recycled through kerbside collections, and on-the-go systems. If a deposit return system was introduced, it could detrimentally impact on the kerbside collection of other aluminium packaging such as aerosols and food packaging.

Another unintended consequence of including aluminium cans in a DRS is that consumers may switch from multi-pack cans to large format PET bottles, to avoid the increase in price; this conflicts with the over-riding need to reduce the amount of single-use plastics.

An overhauled packaging producer responsibility system would help to deliver against many of the current issues – such as increased investment and provision for on-the-go infrastructure, and consistency of kerbside collections – and could be implemented with relative speed.

We are not against DRS; indeed, our industry works closely with systems around the world and they can achieve high recycling rates for drinks cans in the right market conditions. However, in the UK environment we believe that further investment in our existing kerbside collection system, which is envied by many countries around the world, together with effective on-the-go recycling infrastructure will deliver recycling rates for drinks cans on a par with the best performing countries in Europe.

We are therefore calling on decision-makers to thoroughly evaluate all possible policy interventions and their implications, before any decisions are made. This is a once-in-a-generation opportunity to embed a true circular economy framework – we cannot afford to get this wrong.

Read the full report, ‘Achieving an 85% Recycling Rate in Two Years’ here.

By Rick Hindley, Executive Director, Alupro